Sparking Creativity: Cubelets in the School Library Makerspace

As the library media specialist at Avail Academy in Edina, Minnesota, Karen Christensson has been utilizing Cubelets in her makerspace for three years. During each

As the library media specialist at Avail Academy in Edina, Minnesota, Karen Christensson has been utilizing Cubelets in her makerspace for three years. During each

Barbie Atkinson has been using Cubelets for four years in her role as media clerk for Park Hill Elementary in Derby, Kansas. As an educator,

We think about Cubelets in a lot of different ways, but when we were inventing them back in the mid 2000s at Carnegie Mellon, I

It’s the day after Thanksgiving in the USA, and after a holiday hopefully filled with family, gratitude, and a good meal, it feels like the

Kasey Herzberg is the Executive Director of the Challenger Learning Center of Minnesota, a nonprofit working to bring a unique and powerful STEM education center

Across the street from Modular Robotics in Boulder is an industrial air and gas supply store. They’ve got a sign out front with reconfigurable letters

Happy New Year from Modular Robotics! Mary here, the new Educational Community Manager on the Modular Robotics team. I’m so excited to join this vibrant

Like many companies, Modular Robotics has been experiencing stock shortages and shipping delays for the past several months. We know that many of you are

There’s a quirk in the way our brains work. If we can label something with a word, we tend to think we understand it. If

If you want to become a better thinker, it’s time to get curious about complexity. Suppose for a moment that you have the wrong definition

Cubelets FAQs is your place to find answers to common questions about Cubelets robot blocks, orders, and Modular Robotics.

Need help, can't find an answer? Contact the Modular Robotics support team and we'll help you!

Get the details on Modular Robotics shipping policies and sales tax collection for orders in the United States and around the world.

Cubelets are backed by a one year warranty. Need to make a claim, get a replacement, or have questions? Click to get started.

Explore a huge collection of K-12 lessons, activities, guides, training, and more.

Learn everything you need to know to start creating more with Cubelets robot blocks in this handy Getting Started Guide.

Go beyond the building blocks and play with the code inside. Cubelets apps make it easy to create even more with your Cubelets.

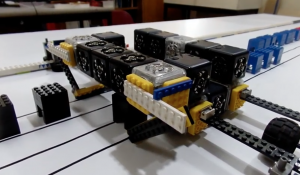

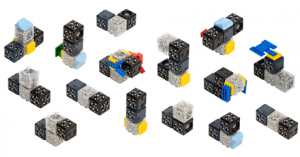

There are millions of robots you can create with Cubelets. Check out these robots to help inspire your inventions.

Cubelets robot blocks are used by educators all around the world to help students explore computational thinking, coding, and STEM.

Bring home the educational teaching tool loved by teachers everywhere. Explore sets designed for learning through play.