The building blocks of better thinkers.

Why blocks?

You can build all sorts of things with blocks. Our world is made of blocks. Wood and brick blocks form our homes. Inside, glass blocks filled with code blocks bend light into blocks of letters that shape our perspectives.

And now – robot blocks can help you build better thinkers.

The experiences we create for students shape them. Cubelets are designed to help students build cognitive skills. So they can solve the biggest problems and teach all the standards we need to cover.

Meet Cubelets.

Cubelets are robot blocks that help teach important problem-solving skills – like collaboration, engineering, design, and computational thinking.

The fast and easy way to build robots.

Cubelets are the only way to build a robot made of a bunch of smaller robots.

Designed to meet you where you are.

Cubelets are versatile. They're used by Pre-K explorers and PhDs.

Loved by educators everywhere.

Find Cubelets wherever learning happens–class, camp, museum, & home.

Learn the biggest lessons from little things.

Cubelets are used to help teach the skills needed to solve life's biggest problems.

An introduction for everyone.

Review Kit Program

Try Cubelets Free for 10 days.

Cubelets Cycle

Reserve an Educator Pack and Lesson Plan Bundle for 1 month, 3 months, or more!

Review Kit Program

Try Cubelets Free for 10 days.

Cubelets Cycle

Reserve an Educator Pack and Lesson Plan Bundle for 30, 60, or 90 days.

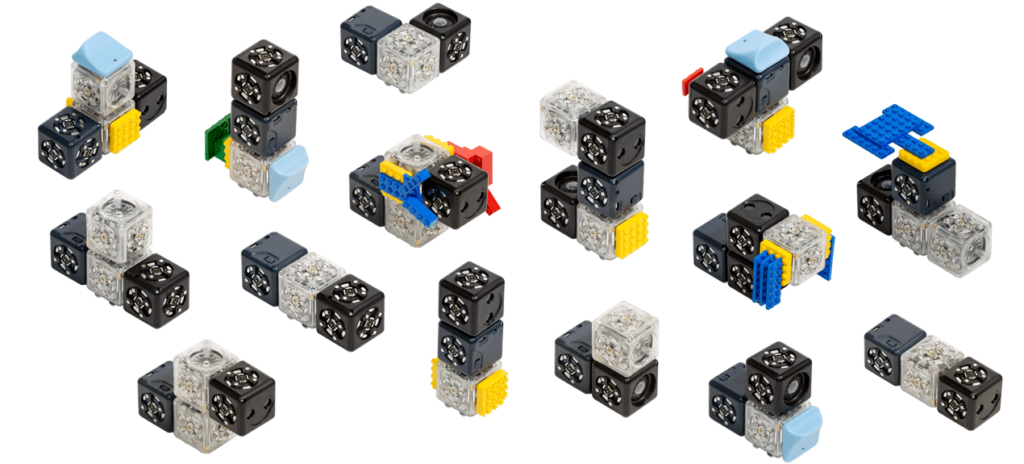

Just like building blocks, only smarter.

You’ve never built with blocks like these. Cubelets are the only way to build a robot where you build with a bunch of tiny robots.

Combine the 17 unique kinds of Cubelets in different ways to create countless robot constructions. Every design is a new robot construction and it all starts when you combine the three basic categories of Cubelets.

Want to know more?

Explore how Cubelets work with the Getting Started Guide. Or check out some robot ideas to see what you can build.

Great for... everyone.

Cubelets are for anyone ages four and up. Don’t let their age-friendly rating fool you! Cubelets are easy to start and grow more challenging as you learn more.

Easy, to start.

Cubelets’ unique design makes robot-building simple. Their size and magnetic connections are perfect for users of all skill levels. No need to code – the behavior emerges from your construction.

If you can build with blocks you can build with Cubelets.

Then, simply complex.

The more you discover about Cubelets the more complex they become.

There is always something to learn and discover with Cubelets. When you’re ready, free Cubelets apps help you change how any Cubelet behaves. Endless possibilities.

Data Logger.

Learn how Cubelets “talk” by visualizing block values or save the data for analysis.

Personality Swap.

Discover how swapping a Cubelet’s Personality changes the way it behaves.

Blockly Coding.

Build new Cubelet behaviors with drag-and-drop programming.

C Coding.

Build new Cubelets programs with text-based coding.

Loved by educators from Vermont to Vietnam.

You’ll find people who love Cubelets everywhere from camps to museums, makerspaces, classrooms, and living rooms. Cubelets are a trusted sidekick wherever learning takes place.

Cubelets are accessible to nearly anyone and versatile enough to teach more than STEM, making them the perfect tool to get every student involved and working as a team.

You don’t have to take our word for it, learn more from the educators that rely on Cubelets in the classroom.

Support comes standard.

Cubelets are more than amazing robot blocks – they’re an entire system designed to help you teach and learn.

Cubelets are supported by:

Or get everything you need to bring Cubelets to your classroom with a Cubelets Lesson Plan Bundle.

Explore the educational resources or check out the administrator checklist to see how Cubelets have you covered.

Little robots, big lessons.

Cubelets teach everything from design thinking to engineering, collaboration, complexity, math, and more. Even advanced ideas like abstract modeling, systems thinking, and emergence can be explored with these deceptively simple robot blocks. Cubelets help you build better thinkers.

Pre-K – 2nd Grade

- Robotics basics.

- Cause and effect.

- Gross motor skills.

- Speaking and questioning.

- Sorting.

- Sequencing.

2nd – 5th Grade

- Computational thinking.

- Critical thinking.

- Design & engineering basics.

- Networking basics.

- Collaboration skills.

- Pattern recognition.

5th Grade +

- Computer Science basics.

- Coding smarter.

- Parallel programming.

- Systems thinking.

- Complexity basics.

- Design thinking.

- Networks.

- Abstraction.

The principles of better thinking.

Cubelets are building toys for building new mindsets. They’re for anyone with an open mind who wants to learn the skills needed to solve big problems. To explain what all this means is to explain what Cubelets are really for.

Cubelets are the building blocks of better thinkers, and their design helps students practice the principles of better thinking.

Want to take Cubelets for a test drive?

We know you’re going to love Cubelets; that’s why we proudly offer educators a free review kit. Take Cubelets for a 10-day test drive.

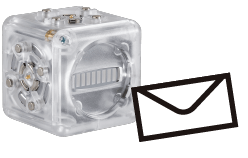

Questions?

We’re here to help you get the most out of Cubelets. Send us a message to start the conversation!

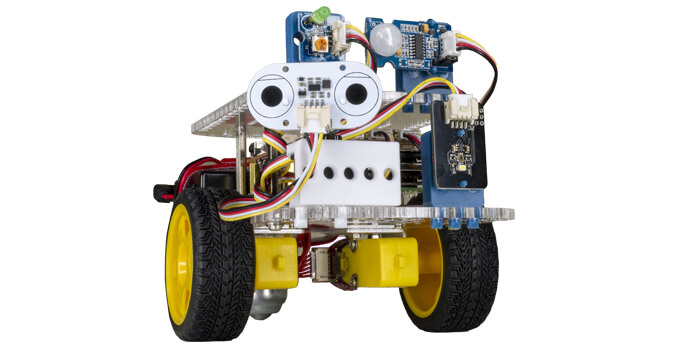

Need a more traditional robot?

We make those too! Meet GoPiGo the Raspberry Pi Robot for helping you go further with Computer Science.